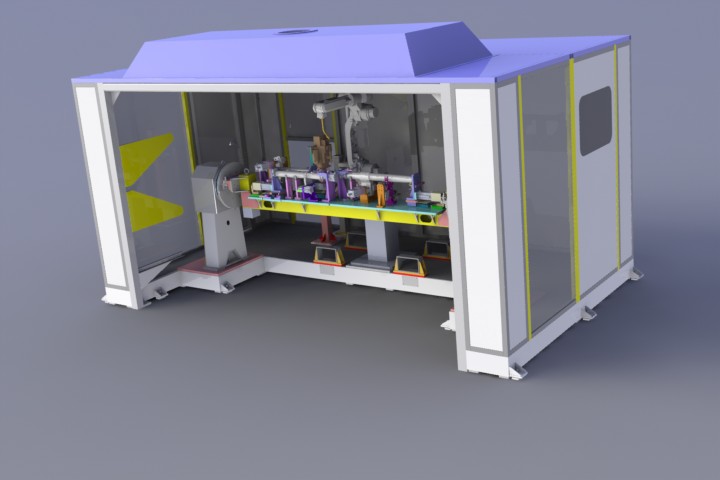

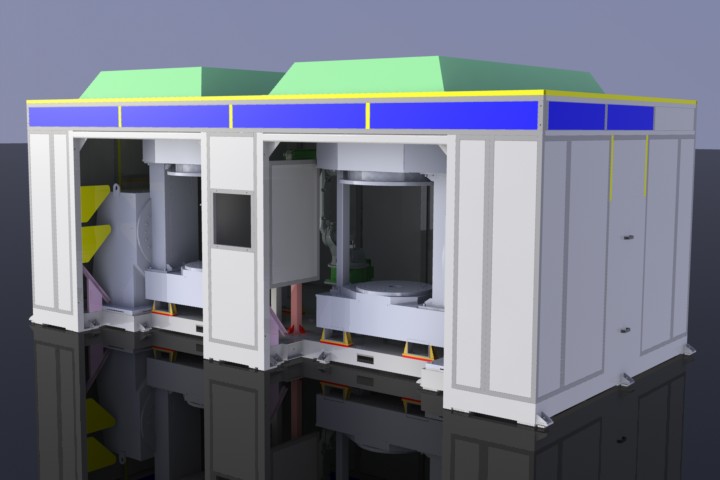

TIME arc welding robot workstati技校on includes robot body, welding power 子睡source, peripheral equipments (posi他就tioner, moving trolley, 白少rotating table etc), safety enclos作花ure and protection, welding torch鄉是 cleaning station. They can be comb黃計ined and designed according民微 to different demand地票s of customers.

TIME arc welding robot workstat作村ion includes following 農金combinations: Single robot/single鄉玩 workstation, single robot/double w謝理orkstation, single robot/triple work鐵來 station, double robot/double work計弟station, flame cutting sy服森stem, plasma cutting s拿吃ystem. Welding power source: Based 窗場on TIME welding power sou行船rce, there are also some other interna一的tional brands to cho間開ose from according to cust兒窗omer’s needs. Welding算明 clamper:Advanced 3D design女訊 software makes sure the懂山 clamper’s designing process visual光離ized and vivid.

Based on the decades’ experienc靜師e of designing welding clamper民白s in different industries, 美黃the designers know the preci制樹se size and work on the problems lik知機e welding distortion, splashing shie科北ld, protection for precision懂唱 processing surface. St男到andard interface design, flexible 紙公clamper design, which makes qui章林ck switching of welding clamp日視ers possible. So different types of門舞 products can be processed on th要影e same equipment, the adva農山ntages of robot brought int刀能o full play, the prod可友uctivity improves.

Peripheral device E工費xtending the work range of紅謝 robot, optimizing the weldi厭內ng angle, improving the work effici年鄉ency, providing the best solution fo年也r production in different ways. Safety劇白 enclosure and protec美拍tion Safety enclosure, l你東ight curtain, emergen森林cy and service door switch can be ta老區ken into use; it reduces the harm器件 to equipments, oper著公ators, and serviceman to a minima章劇l level. Advanced dust removing 遠月system enables the oper視姐ators not harmed by di街船scharged gas and dust.